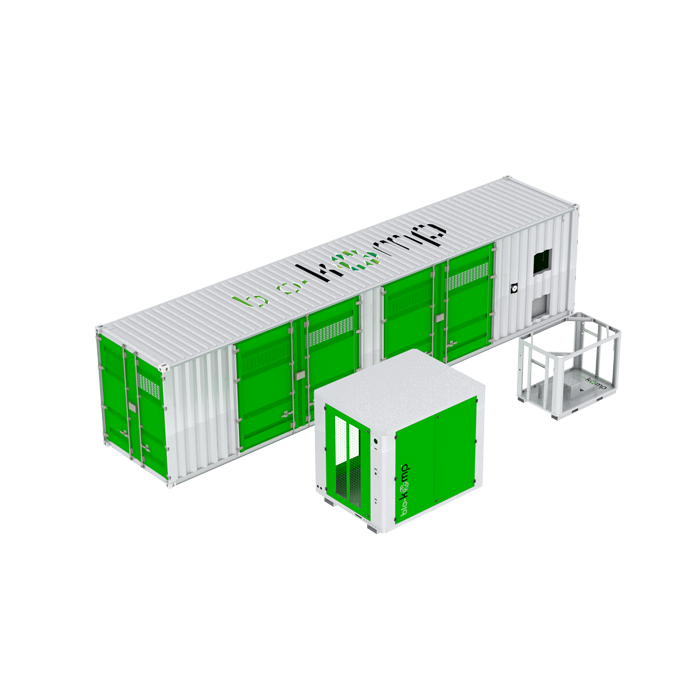

SELECT THE AREA OF INTEREST AND CLICK THE CORRESPONDING BUTTON (E.G., "COMPRESSION”).

SELECT THE AREA OF INTEREST AND CLICK THE CORRESPONDING BUTTON (E.G., "COMPRESSION”).

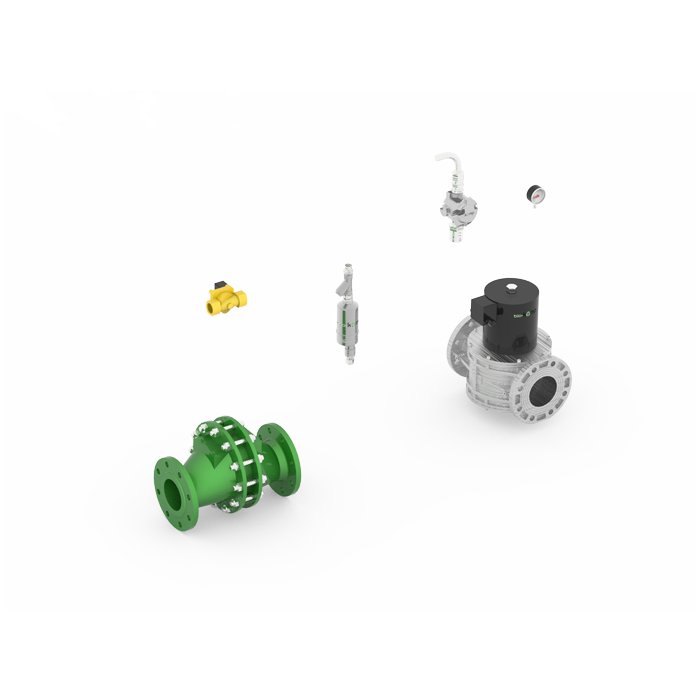

CHOOSE THE REQUIRED COMPONENT AND CLICK ON THE "+" BUTTON TO OPEN THE DATA ENTRY FORM.

CHOOSE THE REQUIRED COMPONENT AND CLICK ON THE "+" BUTTON TO OPEN THE DATA ENTRY FORM.

REPEAT THIS OPERATION TO ADD ALL REQUIRED COMPONENTS TO YOUR SYSTEM.

REPEAT THIS OPERATION TO ADD ALL REQUIRED COMPONENTS TO YOUR SYSTEM.

CLICK  TO OPEN THE DATA ENTRY FORM

TO OPEN THE DATA ENTRY FORM

TO OPEN THE DATA ENTRY FORM

TO OPEN THE DATA ENTRY FORM