your gas

treated and compressed

at higher level

AIR SERIES

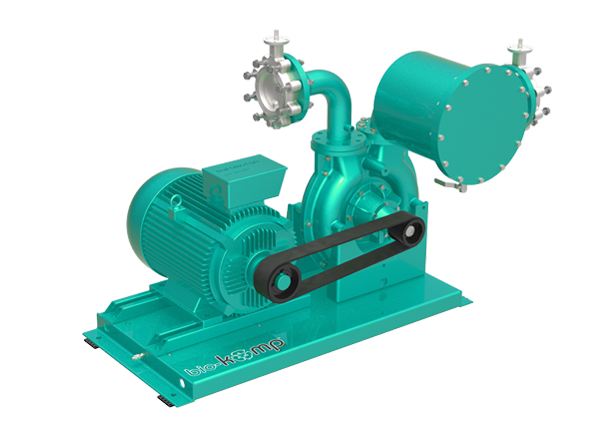

Biokomp air compressors can be applied to a multitude of different uses, whenever there's a work to be done efficiently and safely.

As different applications call for different types of air compressors, biokomp supplies many types of air compressors from centrifugal blowers to reciprocating piston air compressors and rotary screw air compressors.

The selection of the available models ranges from the low pressure air blowers wherever flow is needed for exhausting, aspirating, cooling, ventilating, conveying, to high pressure air piston compressors that will supply a heavy manufacturing facility with constant and reliable air for plant operations.

As different applications call for different types of air compressors, biokomp supplies many types of air compressors from centrifugal blowers to reciprocating piston air compressors and rotary screw air compressors.

The selection of the available models ranges from the low pressure air blowers wherever flow is needed for exhausting, aspirating, cooling, ventilating, conveying, to high pressure air piston compressors that will supply a heavy manufacturing facility with constant and reliable air for plant operations.

Our air compressors can be designed with vertical or horizontal air receivers, with different stages of oil filtration, dehumidifiers and moisture removal systems, and soundproofing canopies.

NATURAL GAS SERIES

NATURAL GAS SERIES

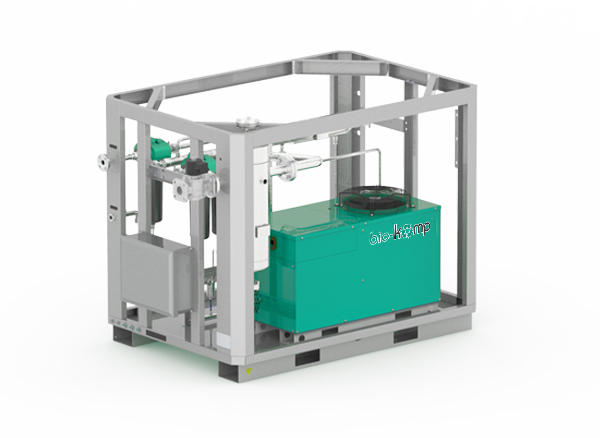

Biokomp natural gas compressors provide a safe, reliable source of compressed gas for power generation and other typical natural gas industry processes.We've been designing and manufacturing high quality natural gas compressor products since the launch of our business.

Our NG compressing units meet the unique challenges that pertain to the natural gas industry: Providing 24/7 gas compression service in many demanding applications including turbine fuel supply, well head gas recovery, and gas transfer. Biokomp 's NG compressors stand out thanks to their dependability, simplified maintenance, reduced operational costs and an assortment of flexible packaging options.

In particular, the most distinctive features of Biokomp NG compressors are:

Maximum Efficiency

Large Pressure Range

Large Capacity Range

Smooth Operation

BIO-METHANE SERIES

BIO-METHANE SERIES

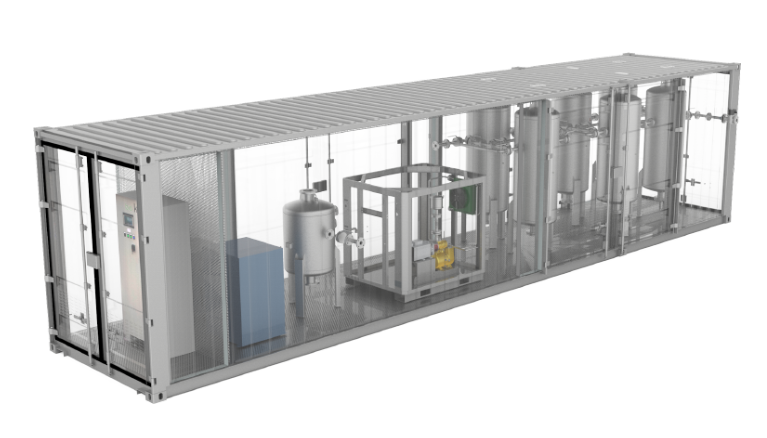

Biogas upgrading is a process whereby most of the CO2, water, H2S, and other impurities are removed from raw biogas.

Biogas upgrading is a process whereby most of the CO2, water, H2S, and other impurities are removed from raw biogas. Because of the highly corrosive nature of some components, the equipment needed for a reliable upgrading operating plant requires expertise and professionalism.

Depending on the production processes and the type of organic matter used, biogas may require treatment to remove toxic gases such as hydrogen sulfide and volatile siloxanes.

Biokomp has developed a series of modern biogas treatment and compression plants that use several purification processes to supply a clean biogas to the CO2 removal system.

BIOGAS SERIES

BIOGAS SERIES

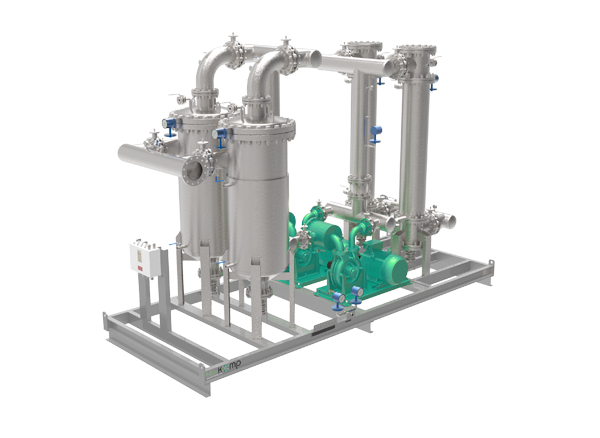

Biokomp designs and manufactures complete Biogas Processing Systems (Filter skids, Blower Skids, Compressor Skids, Chiller Skids) to extract / receive raw biogases from landfills, wastewater treatment plants, digesters, and other sources.

Biokomp designs and manufactures complete Biogas Processing Systems (Filter skids, Blower Skids, Compressor Skids, Chiller Skids) to extract / receive raw biogases from landfills, wastewater treatment plants, digesters, and other sources.Our processing systems can be tailored to meet specific requirements of the biogas application process, from gas stream moisture removal to outlet gas temperature conditioning. Biogas units range therefore from basic waste gas extraction and combustion to multi-pipeline gas-to-energy projects.

Biogas Recovery Systems use side channel or centrifugal blowers to boost the gas pressure, in order to transfer the gas from the digester to the application.

Biogas Compression Systems, instead, are utilized by sites with more aggressive gas processing requirements. These systems typically demand a discharge pressure greater than 5 bar(g), and use positive displacement compressors coupled with pre- and afterfiltration systems, air-cooled radiators, gas-refrigerant dryers or water-refrigerated chillers, and final activated carbon reactors or molecular sieves for ultrafine purification for special applications.

Biokomp Biogas Processing Units are often designed per project requirements, and are always provided as completely pre-engineered, pre-assembled, pre-conduited, pre-wired and factory pre-tested. The mechanical skids and all electronic panels are supplied to the Customer for fast on-site installation and immediate start-up, in order to keep pace with the stringent incentivation deadlines of renewable projects.

INDUSTRIAL GAS SERIES

INDUSTRIAL GAS SERIES

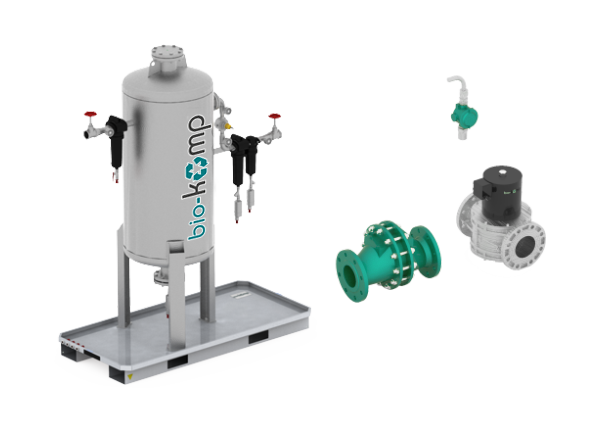

Biokomp has been providing industrial compression solutions to the chemical/petrochemical, steelmaking, food & beverage, and automotive markets.

Biokomp has been providing industrial compression solutions to the chemical/petrochemical, steelmaking, food & beverage, and automotive markets. Our quality, performance, and ease of routine maintenance allow us to find a presence within these industries.

We can supply our engineered solutions for the specialty gas and chemical processing industries worldwide.

Our state-of-the-art products are the top choice of industrial gas and renewable energy companies.

Biokomp works closely with our clients to design, fabricate, test and commission custom-made products from hydrogen boosters to alternative energy equipment such as fuel cell compressors, heavy hydrocarbon removal systems, low-density gas conditioning.